Increased efficiency for waste disposal companies

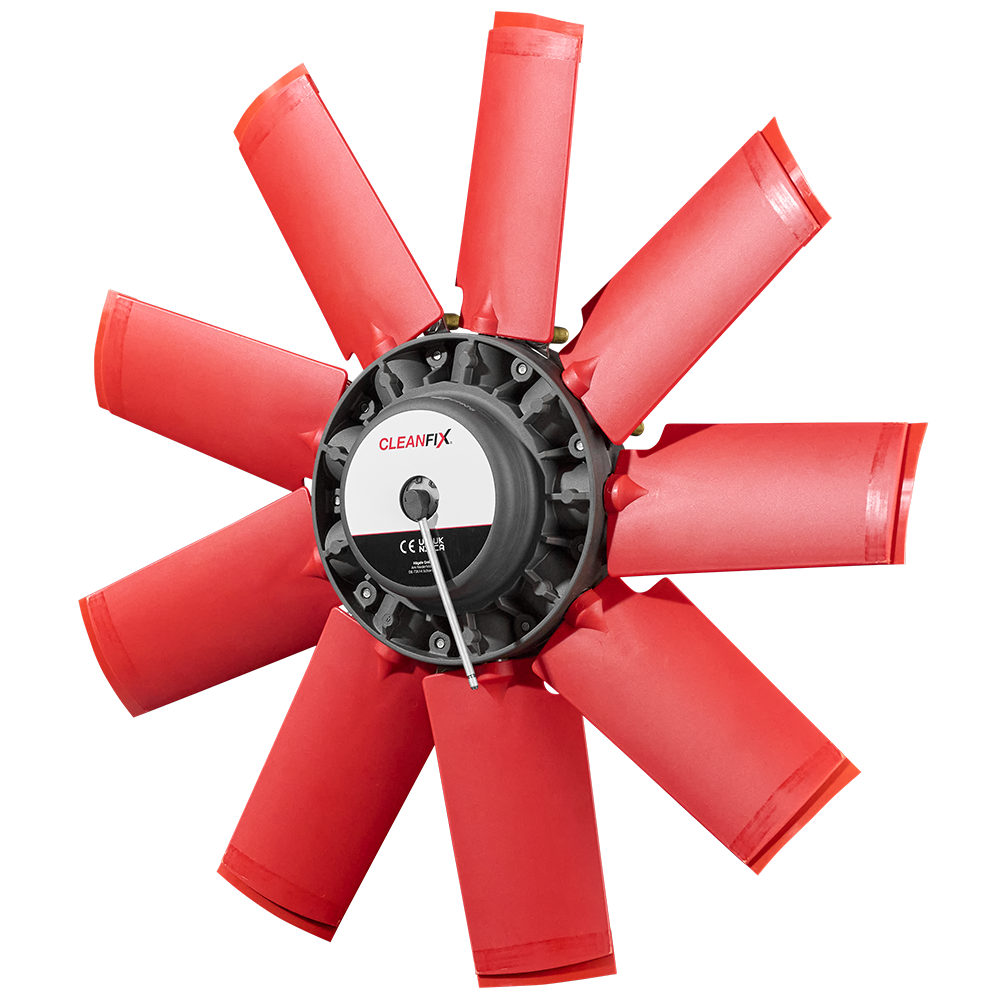

In recycling centers and composting plants alike, machines with Cleanfix reversible fans are simply much more durable.

Machines in waste management companies are exposed to high levels of dust. As a result, the radiators of garbage trucks, excavators, bulldozers, balers, compactors as well as complex sorting and shredding systems become clogged after a short time. Contamination from shredded waste, wood, paper, cardboard, plastic, or shredded biomass in composting plants clogs the radiators. This is exactly where Cleanfix reversible fans offer the ideal solution.

Until now, contaminated radiators resulted in regular cleaning intervals, lengthy maintenance work, and often repairs too. Cleanfix reversible fans prevent such downtimes during a recycling plant’s operation. By reversing the air flow, the Cleanfix reversible fan ensures that the radiator is cleaned in a matter of seconds. Existing machines should therefore also be retrofitted with Cleanfix!

Cleanfix reversible fans are now used by recycling companies worldwide in all areas of waste management, including sorting plants, paper recycling, composting plants, or landfill technology. Machines for all sectors can continue working in a matter of seconds with a clean radiator: efficient, powerful, and low in consumption.

You can also retrofit your existing machines with a Cleanfix installation kit.

A Cleanfix reversible fan promises a return on investment after just 18 months.

When a radiator is dirty, the machine’s fan requires approximately 8 kW/h more drive power than it does with a clean radiator.

Example calculation:

| Additional costs for fuel: | 936 €/year |

| Additional costs for maintenance: | 1,125 €/year |

| You save: | 2,061 €/year |

Calculation basis: Machine with 250 HP, 40% pollution, 900 operating hours per year, 2.6 l/h consumption, radiator cleaning: 15 min. every 90 days.

Potential production losses due to overheating (at least 50 EUR/h) were not considered.

Therefore, a Cleanfix reversible fan promises a return on investment after just 18 months, without taking into account prevented production losses.

Irrespective of this specific example, using Cleanfix technology can help you save between €1,100 and €4,500 per year, depending on operating hours and machine utilization. This ensures the fan is able to pay for itself even more rapidly.

Taking Korn Recycling GmbH as a case study, find out how Cleanfix reversible fans solve a problem that was bringing the company to a standstill every day. The fans have eliminated maintenance downtime, boosted continuous performance, and resulted in 6% fuel savings.