Innovation in fan technology with maximum efficiency in both directions

Fully bidirectional fan

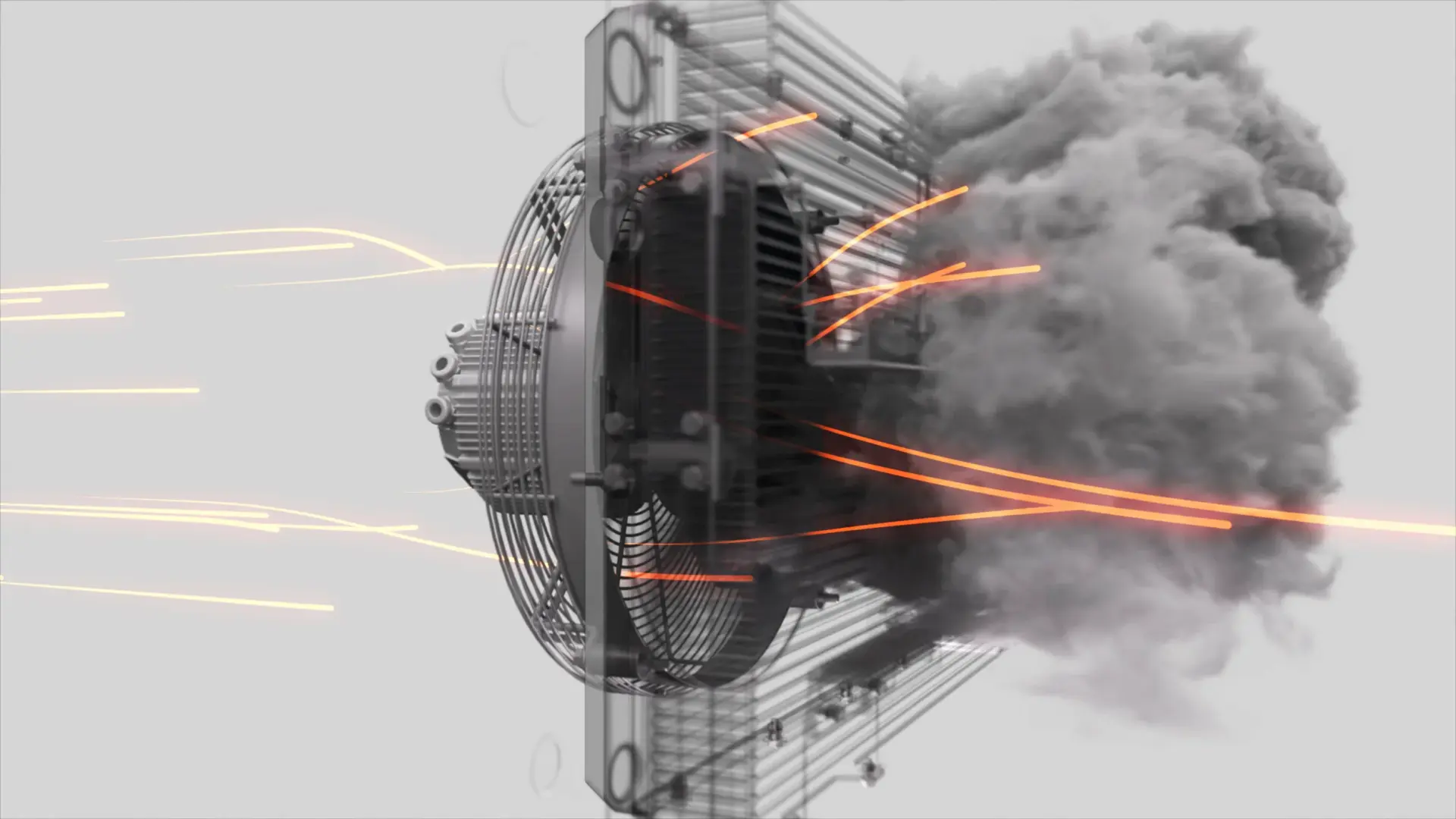

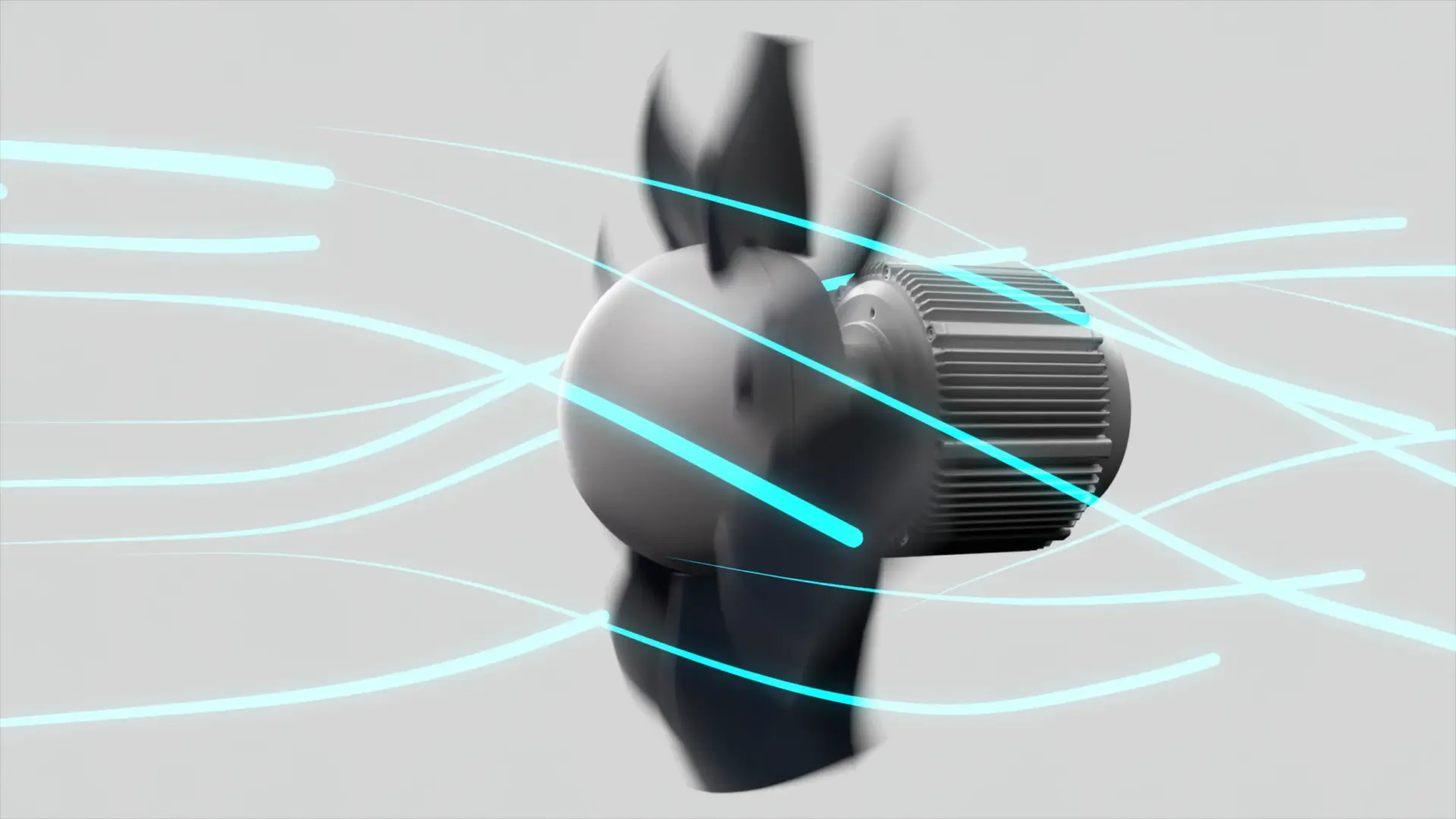

The Fully Bidirectional Fan will be the first fan system for electric and hydraulic drives that achieves identical air performance with maximum efficiency in both flow directions. The inertia-driven blade adjustment ensures that the blades are always correctly aligned for highly efficient cooling and powerful cleaning. The lightweight design reduces inertia, while the aerodynamically optimized blade profiles ensure consistently high air performance. At the same time, the fan combines cleaning and cooling mode in one system, achieving maximum efficiency with minimum energy consumption.

Innovative character

Fully bidirectional fan

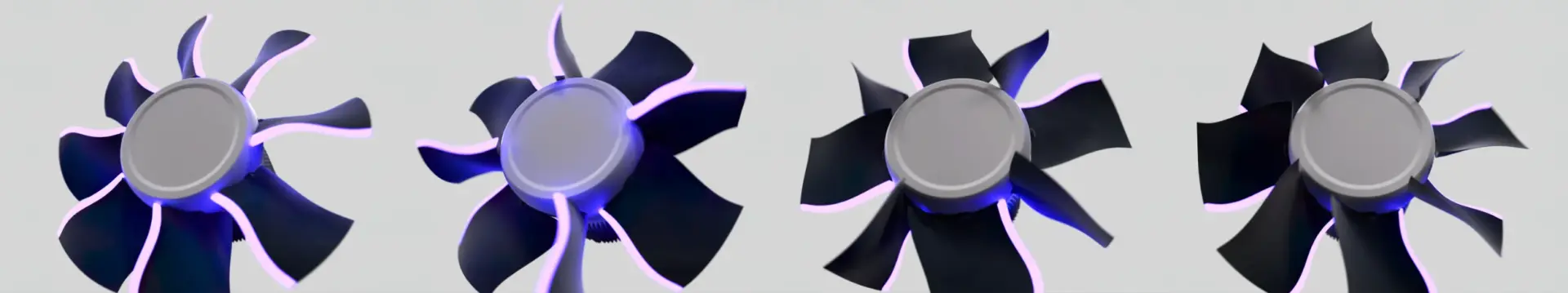

Conventional fans only change the direction of rotation during reversing operation and lose a considerable amount of power in the process. Our prototype combines 180° blade adjustment with aerodynamically optimized geometry. This means that the leading edge remains the same in both directions, efficiency is high and noise levels are low. The media-free, inertia-driven blade adjustment takes place almost at standstill. Ideal for integration into existing machine architectures. The cooling capacity can be precisely regulated or switched off completely if required. All this leads to higher efficiency, lower energy consumption and flexible application options.

Functional advantages at a glance

Advantages

Symmetrical air flow rate

Identical suction and blowing

Adaptable switching

Rapid or smooth switching, depending on requirements

Highly efficient blades

Aerodynamically optimized cooling and blow-out performance

Maximum flexibility

Continuous operation or targeted cleaning as required

Compact design

Simple integration into your machine

Sustainable

Robust construction for durable and long-term use